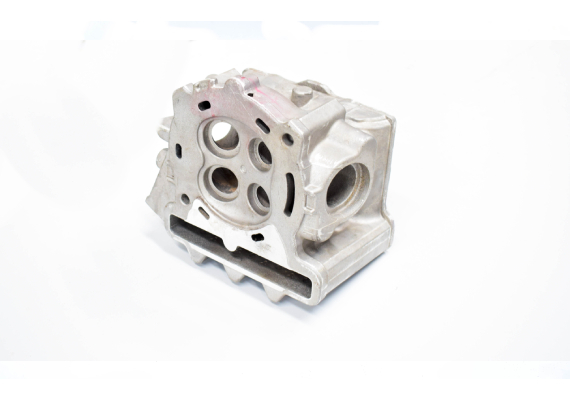

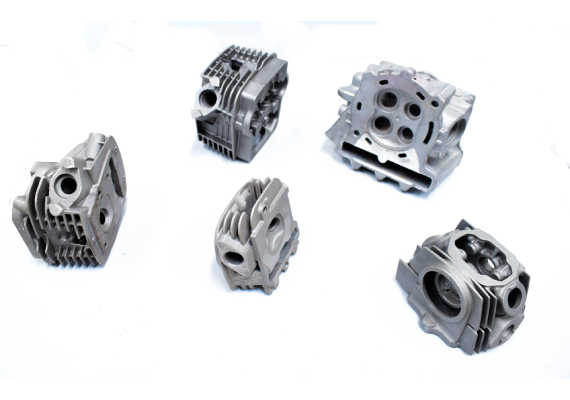

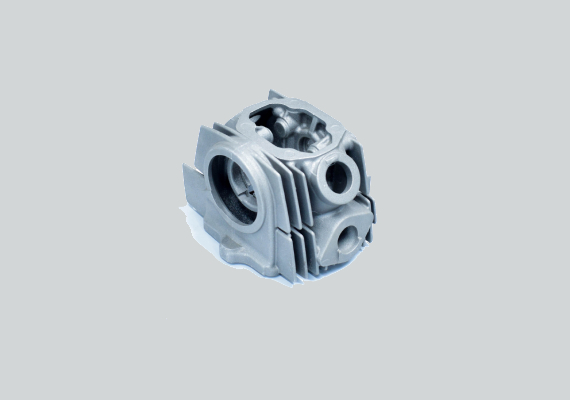

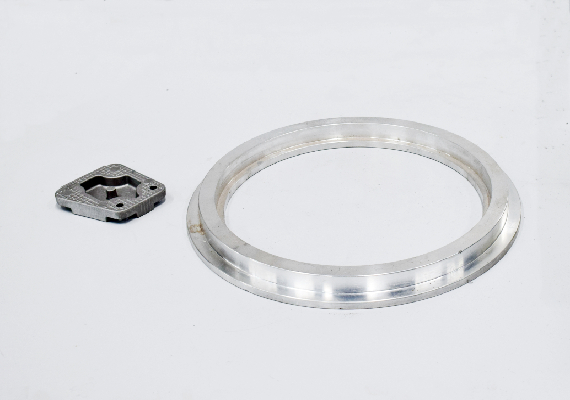

Low pressure Die Casting:

Low pressure die casting, the die is filled with metal from a pressurized furnace, with pressures typically around 0.7 bar by PLC controls. The holding furnace is positioned in the lower part of the vertical die casting machine, with the molten metal injected upwards directly into the bottom of the mould. The pressure holds the metal in the die until it solidifies. One of the main advantages of this process is the precise control of die cavity filling. Molten metal flows quickly and smoothly through the feeding conduits, reducing oxide formation and preventing porosity. This process was created for the production of axially symmetrical parts such as car wheels. However, by employing sand cores within the die, it is also well suited to producing parts with hollow sections and complex geometries