Stationary Gravity Die Casting

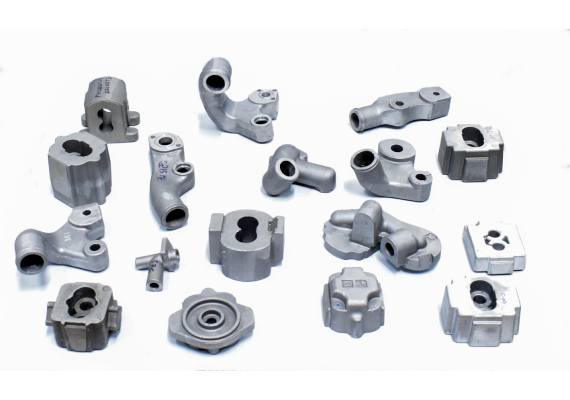

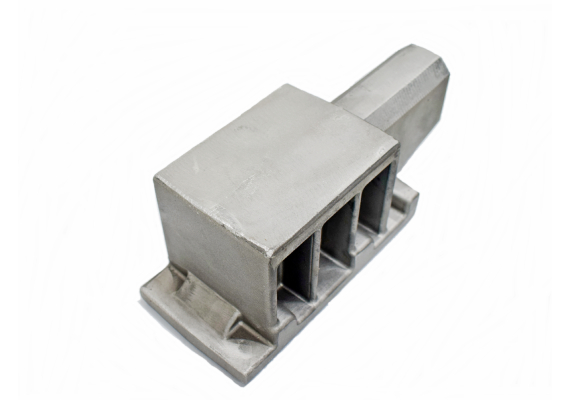

Permanent mould casting get their name from the fact that the process utilizes permanent metal moulds instead of temporary sand moulds for the casting process. Cast iron and Hot die steel is the most commonly used mould materials as it offers great reliability during casting. The cores are made from other metals or sand. The cavity surfaces of the moulds are coated with fine layers of materials that have good heat-resistant properties called as die coat.

The moulds used in casting are pre-heated up to 250 ºC before the molten metal is poured into the cast cavity. Casting has to be done with most care in order to ensure directional solidification and proper thermal balance in maintained throughout the casting process. This is done through a variety of ways including external cooling techniques using water or relevant radiation techniques.

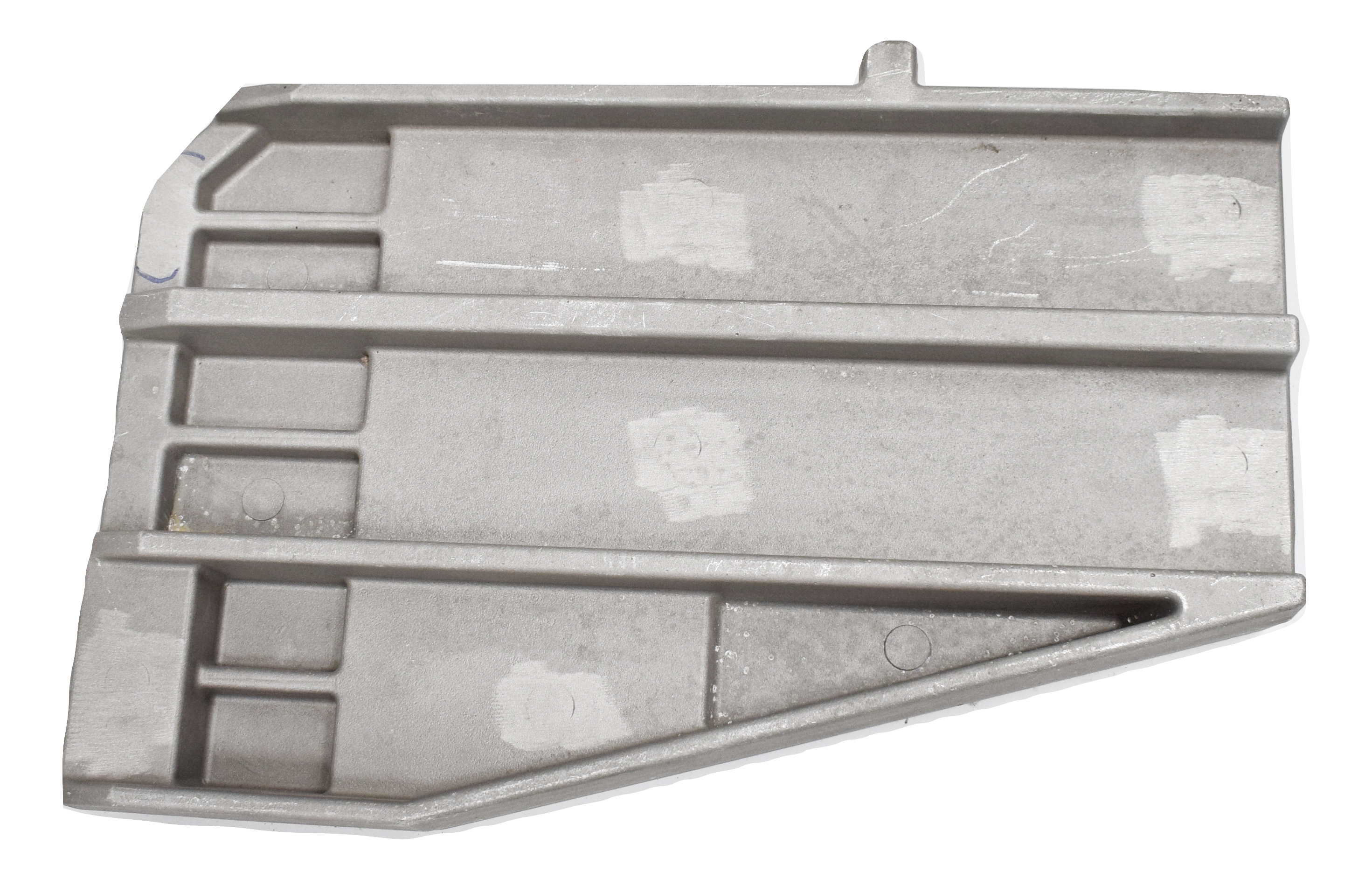

Permanent mould casting, while not offering the same level of design flexibility and ease pattern usage as Aluminium Sand Castings, it has the advantage of offering relatively lower design and development costs as well as production costs. At MCC, we have the expertise to undertake permanent mould castings of complex components of diverse application in various industries.