Tilt Die Casting

Tilt gravity die casting process Low-turbulence version of the gravity die casting process. At the beginning of the casting process, the mold is tilted towards the pouring side, resulting in minimal metallocstatic casting height , or a pouring basin or goose neck is filled in what is called the Durville method.

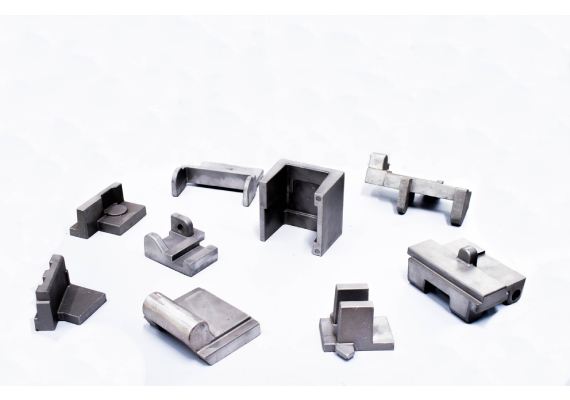

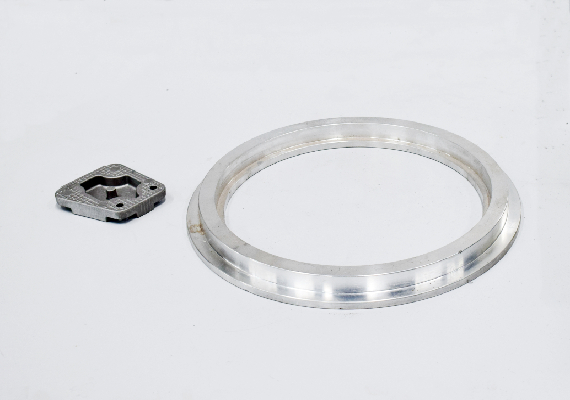

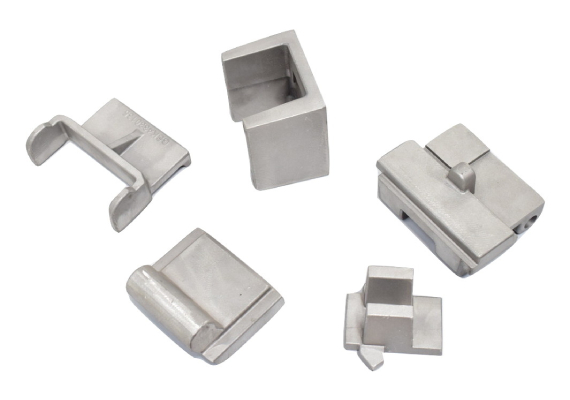

While the mold is filled, it is returned (tilted) to its normal position or the melt flows from the pouring basin and into the mold. This causes the melt to flow into the mold cavity with a low head and at moderate flow rate. This process is used for casting materials with a high propensity to oxidation and foaming, such as aluminum gravity die casting, The tilting towards the pouring side results in a low feed rate in the gate, helping to reduce oxide and foam formation, and the liquid metal can flow into the mold cavity smoothly and with low turbulence. When avoiding flow turbulence, this can also prevent air from being whirled into the casting flow and therefore air inclusions in the structure. At the end of mold filling, the hottest melt is located at the highest point or fills the risers, ensuring good post-feeding. This process uses special tilting gravity die casting machines controlled by PLC is mostly used in the production of parts with multi cavity and complex profiles, yield is also better than the stationary die casting process, At MCC, we use tilting machines that can control the tilting speeds by PLC to get desired repeatability